Lead (Pb) is frequently used as a material in machines in places where X-rays, electron radiation and nuclear radiation must be shielded, such as medical devices and analytical equipment. Lead has special properties (for example the high density of 11.336 kg / dm3 at 20˚C) to shield this radiation in a cost-effective way. This prevents radiation leaks and unsafe situations for users, even in extreme (high voltage) conditions. Thanks to those powerful properties, lead is a special product group for us.

X-ray diffractometer

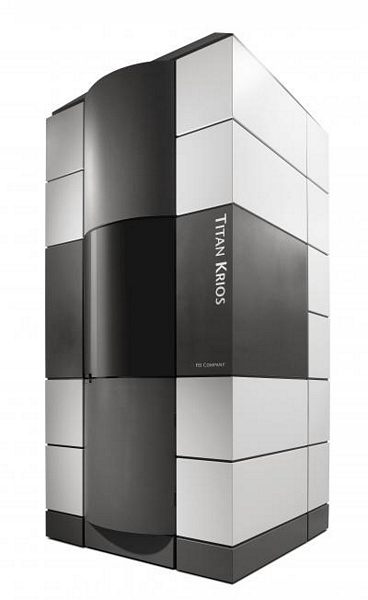

X-ray diffractometer  Electron microscope

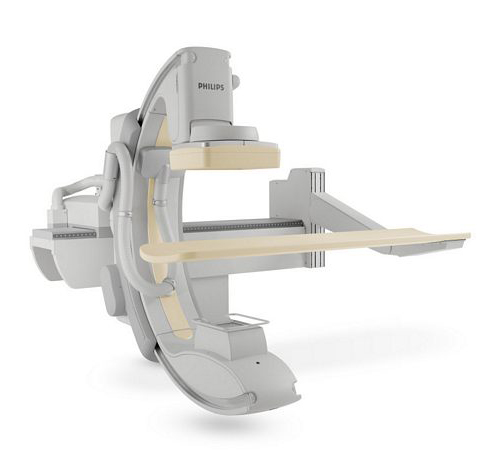

Electron microscope  Medical X-ray scanner

Medical X-ray scanner Our lead products are used in various sectors where ionizing radiation is involved. Ionizing radiation is used in healthcare, for example, when taking X-rays, a CT scan or radiotherapy for the irradiation of cancer. In addition, ionizing radiation is released during the generation of nuclear energy and the production of radioactive substances, but radiation is also used with X-ray scanners for checking baggage, specific measurements in the industry and for scientific research. Consider, for example, material analysis or research into disease cells with the aid of an electron microscope.

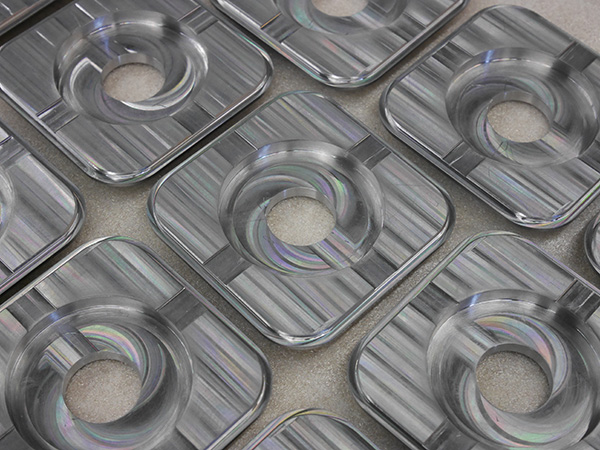

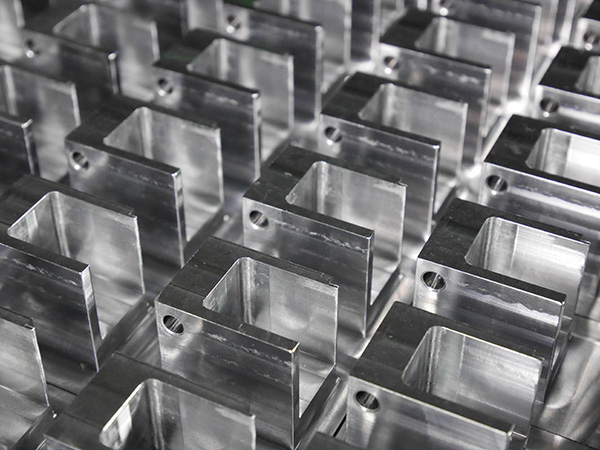

Lead material

Lead material